Cloisonné: Inheritance of Craftsmanship, Enduring Elegance

Chinese Cloisonné, originating from the Yuan Dynasty, reached its peak during the Ming and Qing Dynasties. Over its 600-year history, Cloisonné has been renowned worldwide for its unique style and exquisite craftsmanship. Inspired by ancient ceramics and bronze wares, Cloisonné features floral patterns and classical motifs from ancient bronze wares. The main enamel colors used are peacock blue and sapphire blue, accompanied by red, white, green, and yellow. The cloisonné artworks are full of ethnic artistic characteristics, elegant and delicate, which have been called "Cloisonné" or "Copper-wire Inlay Enamel" by later generations. It is one of China's famous specialized metal crafts.

Cloisonné art during the Qianlong period

During the Qing Dynasty Qianlong period, it was the heyday of cloisonne enamel art. During this period, painting art and enamel craftsmanship were perfectly combined, making the development of cloisonne reach its peak. In the past, cloisonne artworks were exclusively for the use of the imperial palace and nobles, symbolizing power and status. In royal places like the Forbidden City and the Summer Palace, we can still see very few precious cloisonne art pieces. According to historical records in the 48th year of Qianlong (1783), the vessels used for breakfast and lunch included cloisonne bowls with the Five Blessings design, cloisonne bowls with the Harvest design, cloisonne sunflower boxes, as well as gold bowls and plates. During lunch, all the utensils used in front of the emperor were cloisonne bowls, plates, and dishes, while various colored porcelain were used during banquets. This indicates that cloisonne held a very high status in formal banquets, surpassing even porcelain and gold and silver utensils.

The artistic allure of cloisonné

Jiangshan is so beautiful, attracting countless heroes to bow. In this splendid culture of five thousand years, a group of outstanding craftsmen have emerged, who fully exert their talent and crystallize their wisdom into exquisite and unique works of art passed down through the ages. Cloisonne is one of them, a pearl with a long history, elegant design, and dazzling colors, shining brilliantly in the long river of history. Cloisonne combines the production techniques of bronze and porcelain, traditional manual painting and carving skills, and is known as the culmination of Chinese traditional craftsmanship. It possesses artistic effects that are more mellow than jade, more dazzling than jewelry, more delicate than porcelain, and more brilliant than gold. It also showcases a rich and colorful national style and profound cultural connotations, and is hailed as a national treasure of China. The production techniques of cloisonne were included in the list of China's national intangible cultural heritage in 2006.

Production Process of Cloisonne

The production process of cloisonne is divided into seven main steps:

1. Design Draft

Firstly, the designer creates the preliminary drawings, silk work drawings, and blueprints based on the requirements. These design drafts will be used in the subsequent process.

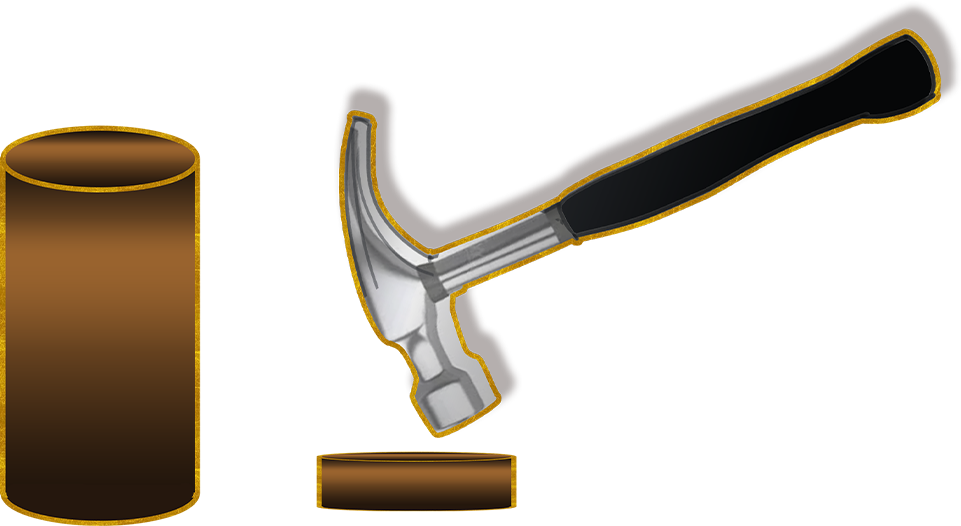

2. Mold Making

First, cut the purple copper sheet into various shapes according to the design requirements and use a hammer to shape them into various shapes of copper blanks. Then, the soldering agent connects different parts together and forms the copper blank shape of the vessel after high-temperature welding.

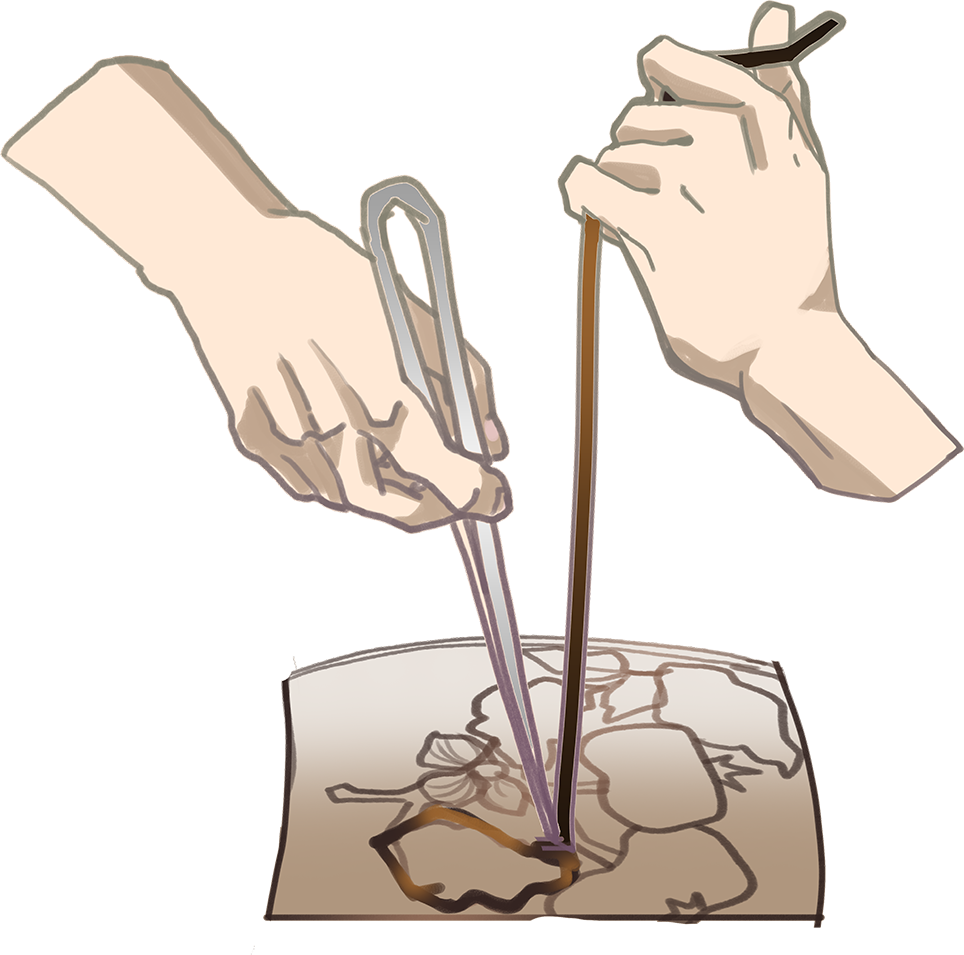

3. Wire cutting process

Use tweezers to cut flattened fine purple copper wire into various exquisite patterns and adhere them to the copper blank. Then, sprinkle silver solder powder on the screen, and after high-temperature roasting, firmly weld the copper wire pattern to the copper blank.

4. Enameling process

After the wire cutting process, the body is subjected to processes such as soldering, acid washing, flattening, and wire drawing, and then the enamel process begins. According to the colors indicated by the pattern, the artist fills the enamel material made of copper wire into the welded copper wire decorative frame using a small shovel.

5. Firing process

After filling the entire body with color glaze, it is put into a high furnace at a temperature of about 800 degrees Celsius for roasting. Ore powder is used as fuel to melt the color glaze into liquid, which forms a splendid solid color glaze on the cooled body. Usually, four or five consecutive firing processes are required until the pattern is completely filled and level with the wire-cut pattern.

6. Polishing process

Use coarse sandstone, yellow stone and charcoal to polish the uneven blue glaze. Any uneven areas need to be repaired and melted with glaze, and then repeatedly polished. Finally, use charcoal and a scraper to flatten and polish the copper lines, bottom lines, and mouth lines without blue glaze, and make them shiny.

7. Gilding process

After acid washing, degreasing, and polishing the polished cloisonné, it is put into the gold-plating solution for gilding. By electrifying, after a few minutes, the gold solution will firmly adhere to the metal parts of the cloisonné. Finally, it is washed with water and dried, and a gorgeous cloisonné product is completed.

The above are the seven main steps in the production of cloisonné, each of which requires exquisite craftsmanship and patient meticulous operation.

Conclusion

The process of creating cloisonné is imbued with artistic allure, and immersing oneself in it is truly awe-inspiring. Incorporating cloisonné into packaging design exemplifies the noble and elegant beauty of traditional Chinese culture. Renowned for its distinctive style and intricate craftsmanship, cloisonné can rightfully be hailed as a treasure of traditional Chinese artistry.